XL3-1000G | XL3-1000G+4

The XL3-1000G equipment is light and compact, with a high load capacity and battery operation. It has a double safety vacuum circuit for the handling and installation of glass on site, according to the EN-13155 standard.

It incorporates new digital control modules in line with industry 4.0. It has battery and vacuum level indicators with light and acoustic alarm. Through an APP you can obtain information about the equipment, diagnostics and alarms.

The reduced dimensions of the equipment allow complex installations in very narrow places such as between the façade and the scaffolding.

The central suction pads are configurable and can be quickly adapted to different sheet formats. Adding extensions (model XL3-1000G+4) allows to increase the gripping surface and capacity for larger sheets.

Optionally available the PI-XL3 Hydraulic piston, which allows manual tipping with load, as well as the CM-XL1 Metal transport and protection box

.

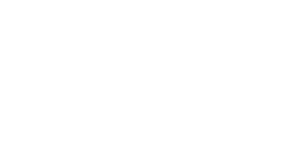

XL3-1000G DRAWINGS

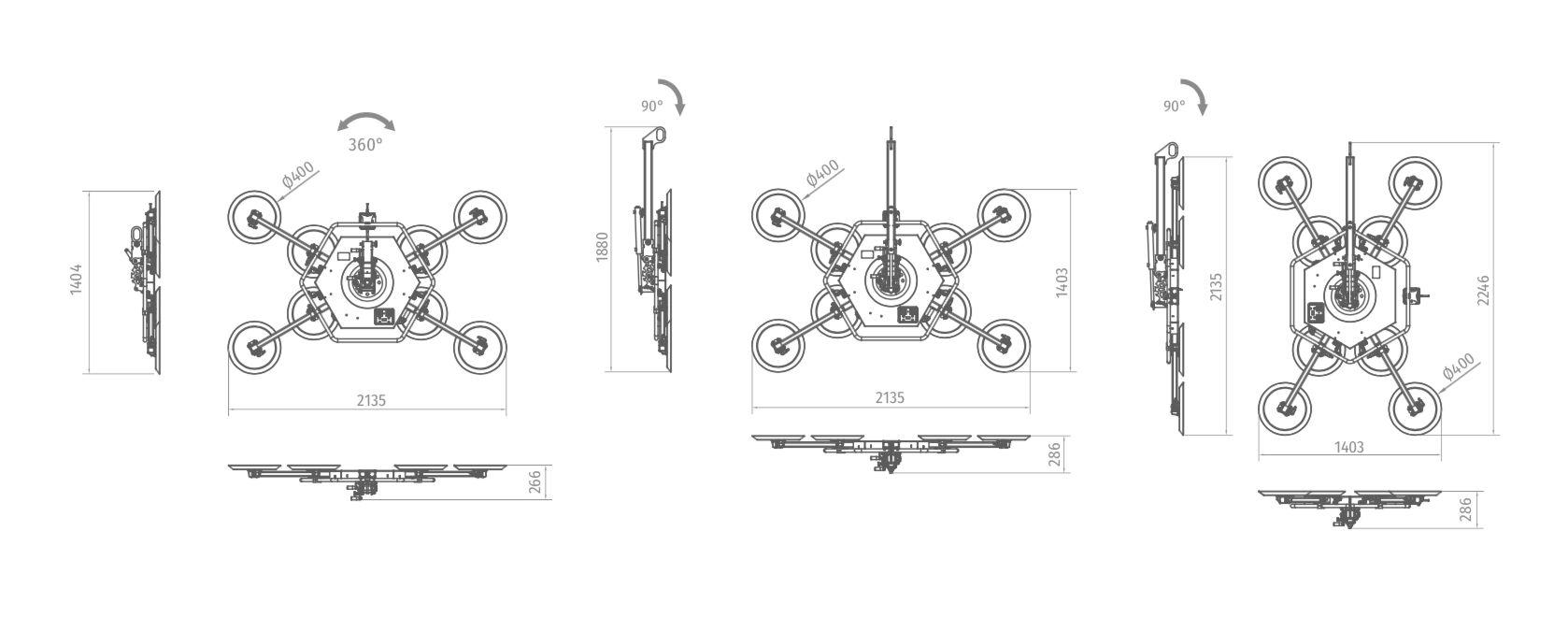

XL3-1000G+4 DRAWINGS

INCLUDED

- METAL BOX

- SUPPORT WITH WHEELS

- FIXED HOLDER EXTENSION 2 SIZES

Optional

- PI-XL3 HYDRAULIC TIPPING PISTON

- MI-04A WIRELESS REMOTE CONTROL

- 4AL -XL3 REMOVABLE EXTENSIONS WITH VACUUM CUPS